MBR Membrane Bio-Reactor

MBR Membrane Bio-Reactor

MBR Membrane Bio-Reactor

The membrane bio-reactor process (MBR process) is the new type waste water treatment technology, which combines membrane separation technology with biotechnology. It uses membrane separation equipment to intercept activated sludge and macromolecular organic matter in biochemical reaction tank and save secondary sedimentation tank. As a result, the concentration of activated sludge is greatly increased. The hydraulic retention time (HRT) and sludge retention time (SRT) can be controlled separately, while the refractory substances are continuously reacted and degraded in the reactor. Therefore, membrane-bioreactor technology greatly strengthens the function of bioreactor through membrane separation technology. Compared with traditional biological treatment method, it has the advantages of high biochemical efficiency, strong resistance to load impact, stable effluent quality, small area, long sludge discharge period and easy to realize automatic control. It is the most advanced one at present. One of the new technologies for waste water treatment. Since the 1990s, it has been widely studied and applied in Japan, France, Canada and other countries.

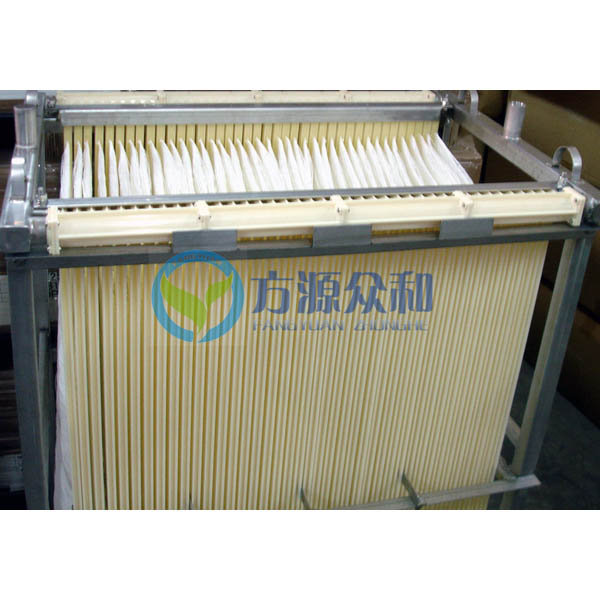

The new generation of imported composite high polymer CSMBR membrane has been improved on the basis of traditional technology as follows:

1. Composite polymer material is used to make the membrane non-polar, hydrophilic, flexible and elastic.

2. Increase the mechanical strength of the membrane several times and completely eliminate the interruption of filament during the operation and maintenance of the membrane.

3. Using patented technology of membrane microporous surface smoothing, CSMBR series membranes have super anti-pollution performance, and also have a very significant cleaning effect.

4. The improvement of micropore uniformity and porosity has saved a lot of equipment investment cost for customers.

The main performance indicators of the latest generation of CSMBR series membrane modules with high pollution resistance and no backwashing are as follows:

Membrane Material: Imported PP or UVDF+Imported Composites (High Antipollution)

Membrane diameter: 350 um

Membrane wall thickness: 40-50 um

Membrane aperture: 0.1 to. 02 um

Permeability: > 7.5 *10(cm_/cm_s.cmHg)

Longitudinal strength: 120 MPa

Porosity: 40-50%

MBR integration MBR in Intermediate-water Reuse

MBR Series Intelligent Integrated Membrane Bio-reactor is a set of integrated water treatment equipment which combines membrane separation technology with biological treatment technology and intelligent control technology. It overcomes the disadvantages of traditional sewage treatment process, such as long process, large area, complex operation and management, and has compact structure and beautiful appearance. It has the advantages of small occupation area, low operation cost, stable and reliable, high automation, easy maintenance and operation, etc. Especially the effluent quality is better than the standard of reclaimed water quality. It is suitable for medium and small scale wastewater treatment and reuse.

Processing capacity: 1-500 m3/d

Scope of application:

Industrial and mining enterprises:

1. Food wastewater treatment

2. Treatment of high concentration organic wastewater such as pharmacy, sugar making, alcohol, leather, paper making, printing and dyeing. The effluent of this kind of wastewater can not meet the requirements of discharge standards by conventional treatment methods, but A2-MBR can be effectively treated with its technical advantages, and the effluent can even meet the reuse standards.

3. Animal husbandry sewage treatment

4. The original sewage treatment stations of all kinds of enterprises have been revamped to meet the standards, water capacity increase, reuse and so on.

Civil buildings:

1. Sewage treatment or reclaimed water reuse system for office buildings, residential districts, hospitals, hotels, schools, stadiums and other civil buildings.

2. Domestic sewage treatment in areas without drainage network, such as tourist attractions, vacation areas, villas, hotels, small residents, stations, toll stations, temporary construction sites, etc.

3. Washing garage, laundry recycling treatment, etc.

Main Model:

Model | Processing Quantity Per Day(T/d) | Dimension(L*B*H)mm |

MBR-1 | 1 | 2000×1200×2000 |

MBR-2 | 2 | 2000×1200×2000 |

MBR-3 | 3 | 2000×1200×2000 |

MBR-5 | 5 | 2500×1200×2000 |

MBR-8 | 8 | 3000×1200×2000 |

MBR-10 | 10 | 3300×1200×2000 |

MBR-15 | 15 | 2500×1200×2400 |

MBR-20 | 20 | 2700×2000×2400 |

MBR-25 | 25 | 3000×2000×2400 |

MBR-30 | 30 | 3200×2000×2400 |

MBR-35 | 35 | 3400×2000×2400 |

MBR-40 | 40 | 3700×2000×2400 |

MBR-50 | 50 | 4200×2000×2400 |

MBR-60 | 60 | 3800×2000×2400 |

MBR-70 | 70 | 4300×2000×2400 |

MBR-80 | 80 | 4400×2000×2800 |

MBR-90 | 90 | 4700×2000×2800 |

MBR-100 | 100 | 5000×2000×2800 |

MBR-120 | 120 | 6000×2000×2800 |

MBR-150 | 150 | 7000×2000×2800 |

MBR-180 | 180 | 7600×2000×2800 |

MBR-200 | 200 | 9000×2000×2800 |

MBR-240 | 240 | 10100×2000×2800 |

MBR-250 | 250 | 10300×2000×2800 |

MBR-300 | 300 | 7000×2000×2800×2 |

MBR-400 | 400 | 9800×2000×2800×2 |

MBR-500 | 500 | 10300×2000×2800×2 |

Notes: 1. The above dimensions include equipment rooms.

2. Carbon steel anti-corrosion or 304 stainless steel can be provided for the box material according to customer's requirements.

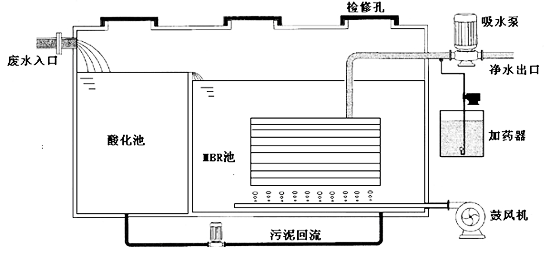

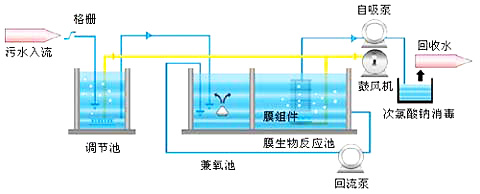

MBR system is mainly composed of the following parts:

1. Intake wells: In the intake wells, the overflow inlet and the intake gate are set up. When the inflow exceeds the system load or the treatment system has an accident, the intake gate is closed, and the sewage is discharged directly into the river or municipal pipeline network through the overflow outlet.

2. Grill: Waste water often contains a lot of impurities. In order to ensure the normal operation of MBR system, all kinds of fibers, residues, waste paper and other impurities must be intercepted outside the system. Therefore, a grid should be set up in front of the system and the grid slag should be cleaned up regularly.

3. Regulating pond: The quantity and quality of sewage collected vary with time. In order to ensure the normal operation of the follow-up treatment system and reduce the operation load, it is necessary to regulate the quantity and quality of sewage. Therefore, the regulating pond is designed before entering the biological treatment system. Sediments need to be cleaned regularly in the regulating tank. Overflow is usually set in the regulating pool to ensure the normal operation of the system under the condition of excessive load.

4. MBR Reaction Pool: Organic pollutants are degraded and sludge is separated in MBR Reaction Pool. As the core part of the treatment system, the reaction tank includes microbial colonies, membrane components, water catchment system, effluent system and aeration system.

5. Disinfection device: According to the requirement of effluent, the system design has disinfection device, which can automatically control dosage.

6. Metrology device: In order to ensure that the system works well, it is necessary to adopt certain metering device to control the parameters of the system. Metering control instruments include flowmeters and water meters.

7. Electronic control device: The electronic control box is installed in the equipment room. Mainly control the intake pump, fan and suction pump. There are two forms of control: manual control and automatic control. The intake pump operates automatically under the control of PLC according to the water level of each reaction pool. The operation of the suction pump is controlled intermittently according to the preset time period. When the water level of the MBR reaction tank is low, the suction pump stops automatically to protect the membrane packer.