EGSB Anaerobic Reactor

EGSB Anaerobic Reactor

EGSB ANAEROBIC REACTOR

I. Equipment Overview

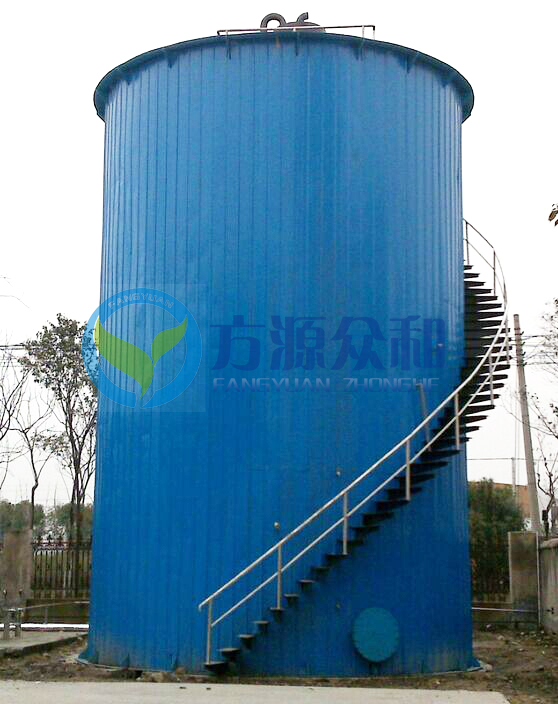

EGSB (Expanded Granular Sludge Bed), a third generation anaerobic reactor, was first developed by Lettinga et al. of Wageingen Agricultural University in the Netherlands in the early 1990s. The structure of UASB reactor is similar to that of UASB reactor. It can be divided into water distribution system, reaction zone, three-phase separation zone and outlet channel system. Unlike UASB reactor, EGSB reactor has a special effluent reflux system. Generally, the EGSB reactor is cylindrical tower, which is characterized by a large aspect ratio, generally up to 3-5, and the height of the reactor in the production unit can reach 15-20 meters. The expanded bed of granular sludge improves the contact between organic substances and microorganisms in wastewater, strengthens the mass transfer effect, improves the biochemical reaction speed of the reactor, and thus greatly improves the treatment efficiency of the reactor.

Expanded Granular Sludge Bed (EGSB) is the third generation of super-efficient anaerobic reactor developed on the basis of the research results of upstream anaerobic sludge bed (UASB) reactor. This type of reactor has not only all the characteristics of UASB reactor, but also the following characteristics.

Namely: 1) high liquid surface upwelling velocity and COD removal load;

(2) The size of anaerobic sludge particles is larger, and the reactor has strong shock load resistance.

(3) The reactor is designed as a tower structure with high aspect ratio and small area.

It can be used to treat wastewater with high SS content and toxicity to microorganisms.

II. Working Principle of EGSB Anaerobic Reactor

EGSB reactor is a specific application of solid fluidization technology in the field of organic wastewater biological treatment.

A certain amount of granular sludge carriers are installed in the EGSB reactor. When organic wastewater and biogas generated from it flow through the granular sludge bed from bottom to top, there will be different relative movement between the carrier and the liquid, resulting in different working conditions of the bed. When the upward velocity of the liquid surface is low, the granular sludge in the reactor remains relatively static, the wastewater passes through the granular gap, and the voidage of the bed remains stable, but the pressure drop increases with the increase of the upward velocity of the liquid surface. When the flow rate reaches a certain value, the pressure drop is equal to the weight of the carrier per bed, and when the flow rate continues to increase, the bed voids begin to increase and the bed expands correspondingly, but the carriers still keep in contact with each other; when the rising velocity of the liquid surface exceeds the critical fluidization speed, the sludge particles will be suspended and the granular bed will flow. The void fraction of the bed increases with the increase of the inlet flow rate, but the pressure drop of the bed is relatively stable. When the inlet flow rate is further increased to the maximum fluidization rate, the carrier particles will lose a lot.

From the working condition of carrier fluidization, it can be seen that the working area of EGSB reactor is the initial stage of fluidization, i.e. the expansion stage (volume expansion rate is about 10-30%). Under these conditions, the inlet flow velocity is low. On the one hand, it can ensure the full contact and mixing of the influent matrix and sludge particles, and accelerate the biochemical reaction process. On the other hand, it has the following advantages: It is beneficial to reduce or eliminate the common bottom load overload in static bed (such as UASB) and increase the reactor's tolerance to organic load, especially toxic substances.

III. Structural Characteristics and Advantages of EGSB Anaerobic Reactor

The main equipment of EGSB consists of EGSB three-phase separator (two layers), gas-water separator, mud-water separator, water sealer, circulation system, etc.

1. inlet water distribution system

The main purpose of the intake and distribution system is to distribute the wastewater as evenly as possible to the whole reactor and to have a certain hydraulic stirring function. It is one of the keys to the efficient operation of the reactor.

2. reaction zone

These include sewage and sludge suspension zones, where organic matter is mainly decomposed by anaerobic bacteria and is the main component of the reactor.

3. three-phase separator

It consists of sedimentation zone, reflux joint and gas seal. Its main function is to separate biogas, sludge and liquid. The sludge is precipitated in the sedimentation zone and then returned to the reaction zone from the reflux slot. The biogas is separated and entered the gas chamber. The separation effect of the three-phase separator will directly affect the treatment effect of the separator.

4. Outlet circulating system and drainage system

The effluent recycling part is different from UASB reactor. The main purpose of EGSB reactor is to increase the flow rate of liquid in the reactor, so that the sludge bed can be fully expanded, the sewage and microorganisms can be fully contacted, the mass transfer effect can be enhanced, and the dead angle and short flow in the reactor can be avoided. The function of the drainage system is to collect the treated water from the surface of the sedimentation zone evenly and eliminate the reactor.

5. chamber

Due to the formation of granular sludge with good sedimentation performance in the reactor, the good natural stirring effect formed by uniform distribution of gas production and high reflux ratio of water inflow, and the design of a reasonable three-phase separator, the sludge with good sedimentation performance can be retained in the reactor, so it has the following advantages:

1. It can be used as the core technology of integrated system which combines environmental protection, energy recovery and ecological virtuous cycle, and has better environmental and economic benefits.

2. It is a very economical technology. It is much cheaper to treat wastewater than aerobic treatment, especially for wastewater with medium or higher concentration.

3. There is little energy demand and a large amount of energy can be generated (theoretically, 0.35 m3 of pure methane gas can be produced per 1 Kg COD removal).

4. The treatment equipment has a high load and occupies less land.

5. The excess sludge produced by the reactor is much less than that produced by aerobic method, and the dewatering performance of the excess sludge is good. Concentration can be done without dewatering agent.

6. Minimum demand for nutrients (COD:N:P=350-500:5:1)

7. High concentration organic wastewater can be treated. When the concentration of wastewater is high, a large amount of diluted water is not needed.

8. The bacteria in the reactor can retain their biological activity and good precipitation for at least one year without feeding wastewater and nutrients. It provides favorable conditions for intermittent or seasonal operation.

9. The system is flexible in scale, large or small, simple in equipment and easy to manufacture.

IV.CHARACTERISTICS OF EGSB ANAEROBIC REACTOR

The characteristics of EGSB are high volume loading rate, short hydraulic retention time, high biomass (up to 60g/L), and long sludge age. Especially because of the internal and external circulation, the mass transfer effect is good. For the treatment of high concentration organic wastewater, the volumetric loading rate of influent can reach 15-30 kg COD/m3/d.

The specific surface area of filter material is large and the activity of biofilm is high.

Gas and water flow in the same direction, the resistance of the filter layer is small, and a higher filtration rate can be obtained.

Strong anti-blocking ability, high oxygen utilization efficiency, unique backwashing form, high degree of automation.

V. Scope of application of EGSB anaerobic reactor

It is mainly used for biological pretreatment of slightly polluted raw water. Effective removal of ammonia nitrogen and oxygen consumption substances in raw water, improve the biological stability of drinking water;

Reclaimed water treatment. Further removal of ammonia nitrogen and S S from secondary effluent of sewage treatment plant can meet the water quality standard of urban sewage recycling and landscape environment water.

Sewage treatment. A variety of combined processes were formed to realize the degradation of organic matter and the removal of SS, COD and PO4-P.

It is suitable for the treatment of high concentration organic wastewater such as starch wastewater, alcohol wastewater and other light industrial food.

VI. Instructions for ordering

1. The ordering unit shall provide detailed water quality information before ordering.

2. According to the water quality, water quantity and floor plan provided by users, our company can design the engineering layout and size map of the water distribution structure of the system.

3. Our company can manufacture special type and special water purification equipment according to the needs of users.