CSTR Anaerobic Reator

CSTR Anaerobic Reator

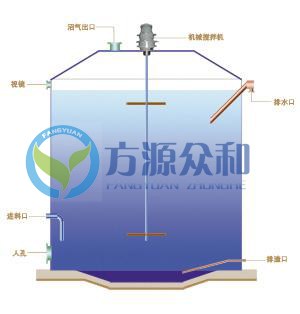

CSTR ANAEROBIC REACTOR

Principle: in a closed tank, the process of liquid fermentation and biogas production is completed. A mixing device is installed in the digester to make the fermented raw materials and microbes in a completely mixed state. The feeding mode is constant temperature continuous feeding or semi continuous feeding operation. The raw materials quickly mixed with all fermented liquid cultures in the fermentor, so that the concentration of fermentation substrate remained relatively low all the time.

Advantages: CSTR process can handle raw materials with high suspended solids content. The material in the digester is evenly distributed to avoid stratification state and increase the contacted chance of material and microbes. By using the mechanical mixing system, the organic suspension in the liquid surface is circulated to the lower part of the reactor, and the reacted gradually and completely to avoid the "cover phenomenon" on the liquid surface of the reactor. The thermal insulation heating system outside the reactor is used to heat the heat insulation system outside the reactor, which greatly improves the gas production rate and investment utilization rate, and makes the reactor work normally all year round. The technology is one of the most advanced anaerobic reactors in the world because of its less land occupation and low cost.

Application fields: used in the treatment of livestock waste in slaughterhouses, cattle, pigs and chickens, biogas production, power generation engineering, and more SS high concentration organic wastewater treatment projects, such as municipal sludge.