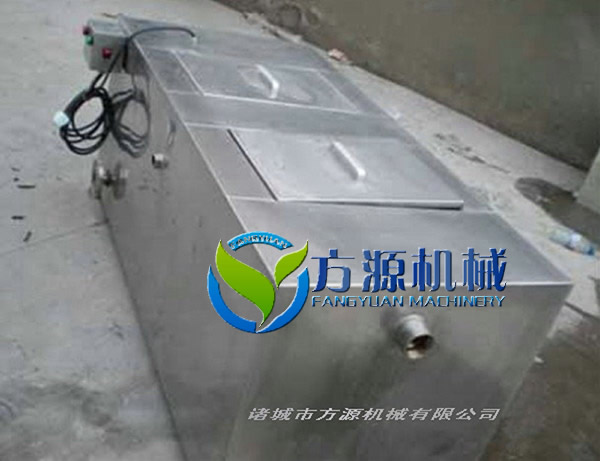

FYSF Oil-Water Separator

FYSF Oil-Water Separator

FYSF Oil-Water Separator

I. overview:

Our company's scientific research and technical personnel in the long-term engineering practice found that at present most of the domestic oily sewage contains more floating matter, suspended matter, and some even contain a large number of sediment, residual food and other impurities. In this case, the probes and solenoid valves used in intelligent oil-water separators often fail or even block the solenoid valves.

For this reason, our company organizes scientific research technicians to tackle key technical problems. After repeated tests and bold practice, we have developed a new generation of FYSF type non-power oil-water separator which is suitable for China's national conditions. It completely realizes that it does not need electricity, only needs regular oil drainage, thus saving investment and reducing operating and maintenance costs. It is not suitable for places with small drainage and high content of oil and impurities, such as catering industry.

II. Scope of application:

It can be widely used in the treatment of wastewater containing animal and vegetable oils in hotels, restaurants, food processing factories, etc. It can also be used in the treatment of industrial wastewater containing mineral oils such as oil fields, petrochemical industry, ships, gas stations, machinery processing and manufacturing, and coking. It can also be used in conjunction with other water treatment devices.

III. Working Principle:

If the oily wastewater is discharged directly into the urban drainage pipeline without treatment, the so-called "gutter oil" will be formed, which will affect the drainage equipment and the municipal sewage treatment plant. The oil concentration of the mixed wastewater flowing into the biological treatment structure can not exceed 30-50 mg/L, otherwise it will directly affect the activated sludge and biofilm. Normal metabolic process.

Under the action of gravity, oil-bearing sewage is separated from the wastewater by natural floatation with the aid of the difference of oil-water ratio.

Through the ingenious design of the internal structure of the product, according to the theory of shallow tank sedimentation, applying the principle of counter-flow separation and the dialectical relationship of turbulent laminar flow, the sewage flowing through the oil-water separator can reduce the flow velocity, flow down and oil droplets float. Practice has proved that the product can remove 90% of the oil slick with a particle size of 60 um or more in the process of sewage flowing through the oil-water separator. On the other hand, the oil content of aquatic animals and vegetable in sewage discharge is lower than the third level (100mg/L) in the Comprehensive Wastewater Discharge Standard (GB8978-1996), and even can reach the second level (15mg/L).

IV. Product characteristics:

1. High technology content: Because of the shallow tank sedimentation theory and the principle of counter-flow separation and turbulent boundary layer, the separation surface of unit tank volume is improved, the effect of oil-water separation is greatly improved, the residence time of wastewater is shortened, the volume of equipment is greatly reduced, the area occupied and the cost are saved.

2. No electricity, no power and cost-saving: The purpose of oil-water separation can be easily realized by using only the liquid level difference formed when sewage flows through the device. This product has many unique features in process principle and structure design, so it works reliably, has small volume and long service life, does not need to add any reagents and medicines, and has no secondary pollution.

3. Easy maintenance according to installation: as long as the intake pipe and outlet pipe can be used, it can be conveniently installed under the washing basin, pot and stove, without the need for special operation and maintenance, only regular oil drainage can be used.

4. It is suitable for all kinds of oils, and the concentration of oil is not limited. It can be widely used in wastewater treatment projects containing natural petroleum and petroleum products, tar and tar fractions, animal and vegetable oils and lanolin, etc., especially in the treatment of oily wastewater in catering industry.

V. Main Technical Parameter:

Item | Technical Parameter | Notes |

Influent oil concentration | Unlimited | |

Oil concentration of effluent | Achieving third-class emission standards | Petroleum 20 mg/l, animal and vegetable oil 100 mg/l |

Oil removal rate | >90% | For oil slick |

Working Temperature | Above 0℃ | |

Working Pressure | Normal Pressure | |

Specific gravity of separable oil | <1 | |

Separable Minimum Oil Bead Size | 60um | |

Floating speed of oil beads | 0.2mm/s |

VI. Specification Parameter:

Model | Processing Ability(m3/h) | Length(mm) | Width(mm) | Height(mm) | Diameter of outlet pipe(mm) |

FYSF-0.5 | 0.5 | 800 | 300 | 300 | 50 |

FYSF-1 | 1 | 1500 | 500 | 400 | 50 |

FYSF-2 | 2 | 1500 | 800 | 500 | 80 |

FYSF-3 | 3 | 2000 | 800 | 500 | 80 |

FYSF-4 | 4 | 2000 | 800 | 700 | 80 |

FYSF-5 | 5 | 2000 | 800 | 800 | 80 |

FYSF-6 | 6 | 2000 | 900 | 800 | 100 |

FYSF-8 | 8 | 2000 | 1250 | 800 | 100 |

FYSF-9 | 9 | 2000 | 1500 | 800 | 100 |

FYSF-10 | 10 | 2500 | 1250 | 800 | 100 |

FYSF-12 | 12 | 3000 | 1250 | 1000 | 150 |

FYSF-15 | 15 | 3500 | 1250 | 1000 | 150 |

FYSF-20 | 20 | 4000 | 1500 | 1000 | 150 |

FYSF-30 | 30 | 4000 | 2000 | 1000 | 150 |

FYSF-40 | 40 | 4000 | 2500 | 1000 | 200 |

FYSF-50 | 50 | 5000 | 5000 | 1000 | 200 |